The hopper rubber

The hopper rubber is a grinding tool associated with the spread of the ancient Greek world throughout the Mediterranean. Its presence is certified at certain Greek or Greek-influenced sites in the southeast of France during the second half of first millennium BC (Py 1992; Chausserie-Laprée 1998; Frankel 2003; Jaccottey et al. 2013). Beyond the Mediterranean, it has likewise been detected, albeit rarely, in Iron Age contexts at the oppida of Steinsburg and Gorsleben in Germany (Wefers 2009) and in Czechia, notably Zatec and Krasovice in the west (Frankel 2003: 4) and Moravia in the east (Goláňová 2018).

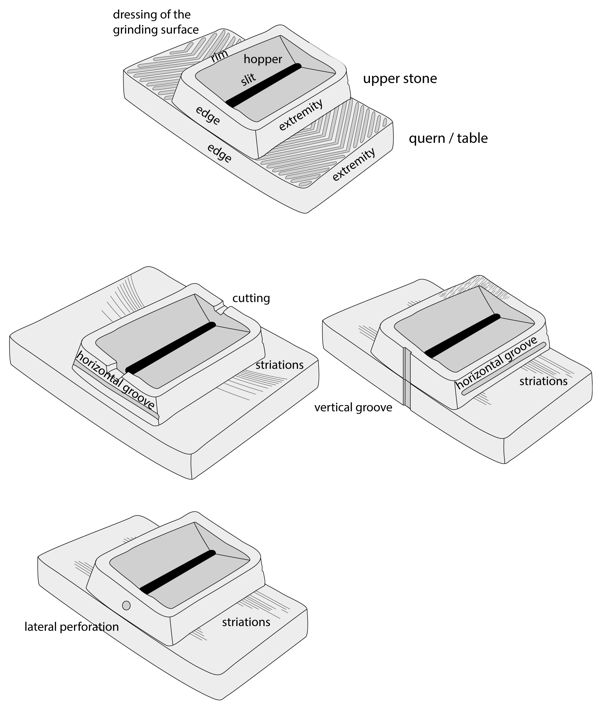

One of the most characteristic features of this mill is the transversal cutting through the upper face of its upper stone reaching its grinding surface (Fig. 1-2) which allows a continual feeding of grains from above. This feature among the mill’s more “standard” forms specific to the Greek world thus takes on the role of a hopper or receptacle (Frankel 2003). Childe (1943) proposed the term hopper rubber for these mills while Moritz advanced the Olynthian mill (Moritz 1958, 46) based on the site (Olynthus) where a very precise study of these mills was carried out by Robinson and Graham (1938). This last term was retained by Frankel who was the first to carry out a thorough classification of the mill (Frankel 2003). It is also noteworthy that Peacock’s recent survey of ancient mills (Peacock 2013, Chapter 3) also maintains this term. It is our position, nonetheless, that the term Olynthian applies to a very particular model characteristic of the Greek world and the east of the Mediterranean and does not reflect this mill’s diversity throughout the Western Mediterranean Basin and Central Europe (Frankel 2003, 2; Py 1992).

We therefore suggest the following two terms for this mill. As a general term alluding to the whole mechanism we propose Hopper Rubber Mill (moulin à trémie in French). For its upper mobile stone, easy to recognise, we suggest hopper rubber (molette à trémie in French). As to its lower stone, in turn, we suggest the more neutral term table (which serves in both English and French) as this element is often difficult to distinguish from lower stones of certain saddle querns (Py 1992; Chausserie-Laprée 1998). It must be noted that there are nonetheless certain criteria that can at times serve to discern them from the lower stones of saddle querns, notably typical dressing patterns (Frankel 2003) and, at least at some sites of the southeast of France, vertical cuttings along their flanks (Chausserie-Laprée 1998).

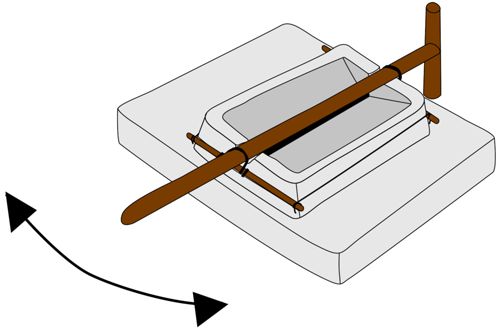

The first reconstruction of the driving mechanism of a standard hopper rubber mill was advanced by Kourouniotes based on a bakery scene depicted on a Megarian bowl (Kourouniotes 1917; Rostovtzeff 1937). The upper stone with a width equivalent to its lower counterpart was driven with a sideways oscillating motion by means of a long bar or handle set in the opposite slots of the upper stone and fastened by a vertical pivot (Fig. 1). We propose, however, to abandon the term “lever” at times serving to describe the long handle (e.g., Moritz 1958, 45) as the motion applied to this mill is not vertical but horizontal. The axis of the slit is therefore perpendicular to the upper stone’s operating axis. An in situ find at Gamla in Israel (Frankel 2003: 8) and other similar stones in Sicily and in Israel bearing arc-like or semi-circular traces of wear on their grinding surfaces appears to confirm this hypothesis.

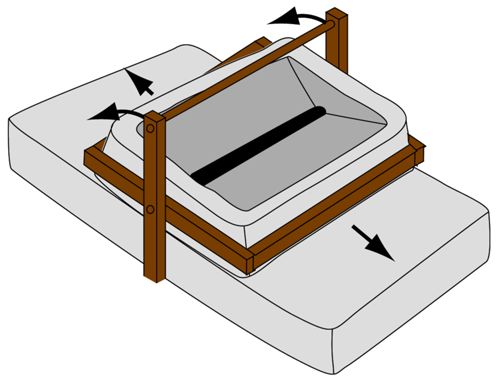

A detailed study of these types of upper stones from the site of Martigues (Chausserie-Laprée 1998, 227-230) in southern France has led to an alternative reconstruction of this mill’s driving mechanism (Fig. 2). Upper stones of equal width to their lower counterparts were operated with a straight, to and fro motion in the longitudinal axis of the lower stone (as evidenced by a convexity of the longitudinal profile of the grinding surface). The hopper slit is therefore perpendicular to the operating axis of the upper stone, allowing the grain to spread out evenly along the grinding surface. Vertical adjustment cuttings, cited above, were carved into the upper stone’s edges so as to align with identical cuttings on the edges of the table. A second type of shallow horizontal fluting extends along the stone’s longitudinal edges, without reaching its far endsThese hollows allowed attaching a wooden frame or rig around the lower stone mounted by an upright crossbar serving to drive the upper stone with a to and from motion. This reconstruction, confirmed by experimentation (Chausserie-Laprée 1998, 229), yields traces of polish on the surface of one of the two rims and one of the angles of the upper stone.

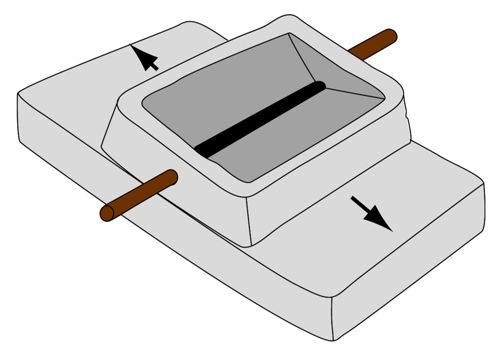

Finally, there is evidence of yet another means of driving these mills based on a case from the site of Karanis in the Egyptian desert (Husselman 1979) where an upper stone bears opposite blind holes cut into its short edges. These holes must have served for horizontal wood handles to apply a to and fro motion (Fig. 3).

These different driving mechanisms are examples of the many variations within the type. Frankel in 2003 presented the elements of a solid typology (shape of hopper and upper stone, method of attachment of the handle and dressing patterns) essentially focusing on finds from the eastern Mediterranean. One of the goals of the current study is to offer a standard means of collecting data serving to extend the typological classification to include the hopper-rubber mills of the entire Mediterranean Basin. This standard stems from two databases of the French Groupe Meule (Collective research project entitled Typological and technical evolution of querns and millstones from the Neolithic to 1000 AD)respectively for querns and rotary mills. The work is based on a precisely defined terminology applying standardised directives for drawing to facilitate visualising the features of the mill.

The different fittings and means of traction clearly demonstrate that this type of mill must be grouped into a series of different subtypes and that Frankel’s (2003) initial classification, based on the shape of the upper stone, the form of its hopper, its handle fittings and dressing patterns, is applicable only to the Eastern Mediterranean. The idea of the current study is therefore to go further and lay the foundations to extend the typology of hopper rubber mills to the whole of the Mediterranean Basin and beyond.

To assist future research, this paper advances a standardised data-collection form, an extension of that of the current database of the French Groupe Meule of hand querns and rotary mills, as well as a precise lexicon and standardised directives for drawing this type of mill.

Hopper Rubber lexicon (fig. 4)

The terms serving to describe hopper rubber mills stem from the general “saddle quern” lexicon developed by Hamon et al. (2011) and Jodry (2011). Most are applicable to other types of hand driven mills.

Cutting: opposite recesses, usually on the shorter rims, on the upper stone serving to accommodate the bar to drive the hopper rubber.

Dressing: random or organised (linear pattern) pecking or grooving of the grinding surface to sharpen the mill and enhance its “bite”.

Edge: for hopper rubbers and tables the edges correspond respectively to the long and short sides.

Extremity: for the upper stones and tables the extremities equate with the distal (away from the user) and proximal (closer to the user) sides.

Grips: single or opposite protuberances or lugs on an upper stone serving to grip it with the hands or to attach a driving mechanism. The grips are at times perforated or notched.

Grooves or flutes: shallow horizontal or vertical cuttings along the edge of hopper rubber upper stone serving to attach and hold in place a driving fitting.

Hopper: receptacle on the upper stone tapering downward toward the opening of the slit serving to automatically feed the grains into the mill.

Rim: raised quadrangular edge along the periphery of the upper stone (Frankel 2003).

Slit: narrow opening along the base of a hopper rubber upper stone allowing an automatic passage of grains. The slit can take on different forms (linear, round…).

Striations: fine linear or arc-shaped use-wear traces on the grinding surfaces.

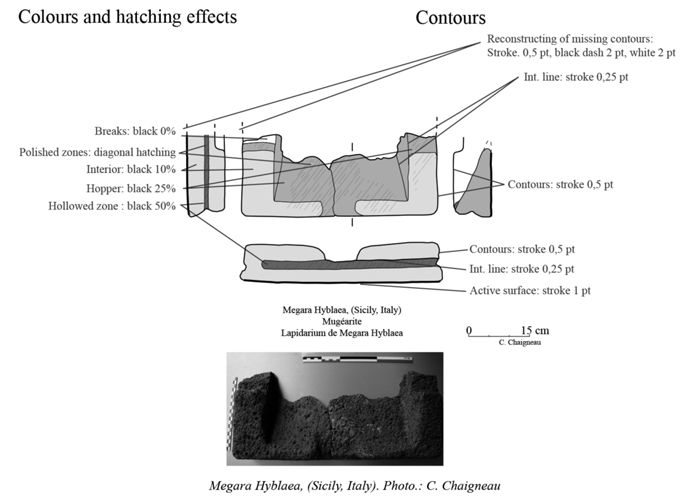

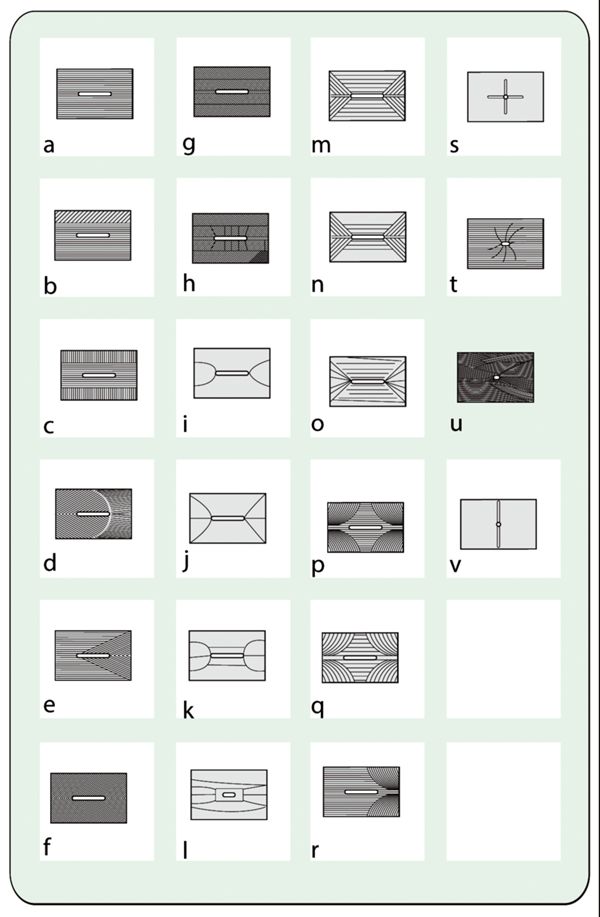

Hopper rubber mill drawing directives

The aim of standardising the means of drawings hopper rubber mills through a series of directives is to facilitate the reading of their different morphological and technical features as well as to depict their dressing patterns or traces of use-wear. This requires a number of different views (1:5 scale) notably of their upper surface and longitudinal and transversal profiles and sections. A view of the grinding surface can be added when the dressing or use-wear traces are visible. The upper stone is oriented according to its direction of use, that is, with the slit placed horizontally when the piece is driven with a to-and-fro motion or with the slit placed vertically when it is driven with a sideways oscillatory motion. A default orientation with the slit in a horizontal position is adopted when its direction of operation cannot be determined with certainty (Fig. 5). When vectorising the drawing with CAD tools, the fills and stokes are identical to those defined for the drawings of querns and rotary querns (Hamon et al. 2011; Jaccottey & Farget 2011).

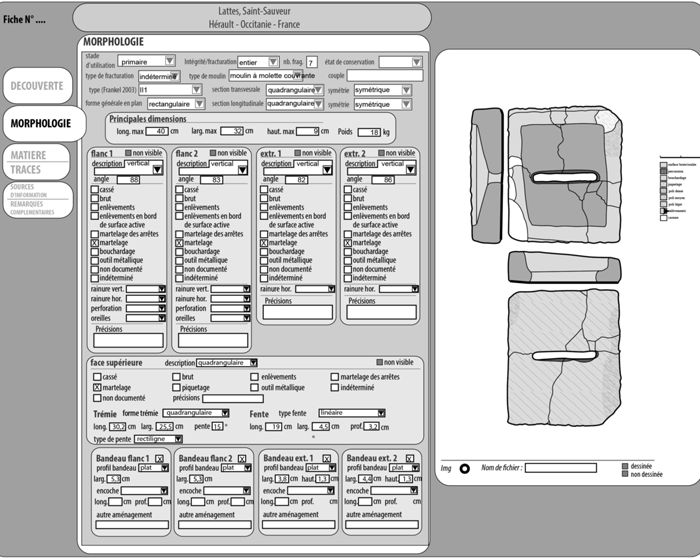

The hopper rubber mill database

This hopper rubber mill database derives from the databases of other types of mills developed in the framework of the Research Project (see above). The “Place of discovery” and “Rock type and Wear” tabs are identical to those of the databases of “saddle querns” and rotary querns (Fig. 6, 8). A specific tab had nonetheless to be designed for the descriptive fields of the morphology of the upper stones of these mills (Fig. 7). Despite the mill’s great diversity, the criteria offer the possibility of a very detailed description.

of hopper rubber mills.

The description of the general type and shape of the hopper and slit follows the typological elements advanced by Frankel (2003). The dimensions are garnered from the mill’s default direction of use (i.e., length from edge to edge; width from extremity to extremity). The study of different assemblages of France, Sicily and Greece reveals the necessity of describing each feature separately, hence the fields labelled edge 1/edge 2, extremity 1/extremity 2, and their respective rims.

The grinding surface is treated in a specific tab common to saddle querns with fields that also serve to describe the rock type and use-wear (Fig. 8). The description of the dressing of the grinding surface proved to be quite complex due to the great diversity of patterns and variations (association of lines, density of lines…). In fact, an exhaustive typology, as noted by Frankel (2003), is impossible (Fig. 9). The database therefore renders it possible, when desired, to check a type following the Frankel typology or, when necessary, add a new type. The typology of the dressing patterns of these types of mills will therefore progressively expand with new entries.

v from Weffers 2009 (CAD: L. Jaccottey).

Conclusions

The step subsequent to defining the drawing guidelines, technical terms, criteria and input mask of the database of hopper rubber mills is to integrate the new tab into the general database of the French Groupe Meule. The long-term objective is to translate it into English and disseminate the information to the international community. This is the first step in setting in motion a new hopper rubber mill typology, analysing the stages of its appearance and diffusion, and attaining a better grasp of its use. Moreover, applying a unified method to describe and analyse the different types of ancient mills (querns, hopper rubbers, rotary querns and millstones) can shed new light on the transition from one type to another.

Bibliography

- Chausserie-Laprée, J. (1998): “Les meules des habitats protohistoriques de Martigues”, in: Entremont et les Salyens, actes du colloque d’Aix-en-Provence, Documents d’Archéologie Méridionale, 21, 1998, 211-235.

- Childe, V.G. (1943): “Rotary Querns on the Continent and in the Mediterranean Basin”, Antiquity, 17, 19-26.

- Frankel, R. (2003): “The Olynthus Mill, Its Origin, and Diffusion: Typology and Distribution”, American Journal of Archaeology, Vol. 107, No. 1 (Jan., 2003), 1-21.

- Goláňová, P. (2018): The Early La Tène Period in Moravia, Studien zur Archäologie Europas, 32.

- Hamon, C., Farget, V., Jaccottey, L., Milleville, A. and Monchablon, C. (2011): “Quelques propositions de normes de dessin et d’une grille d’analyse pour l’étude du matériel de mouture va-et-vient du Néolithique à l’âge du Fer”, in: Buchsenschutz, O. Jaccottey, L., Jodry, F. and Blanchard J.L. (coords), Évolution typologique et technique des meules du Néolithique à l’an mille sur le territoire français. Table ronde de Saint-Julien-sur-Garonne (F) du 2 au 4 octobre 2009, 2011, Aquitania Suppl. 23, 39-50.

- Husselman, E. M. (1979): Karanis Excavations of The University of Michigan in Egypt, 1928-1935. Topography and Architecture, Ann Arbor: University of Michigan Press.

- Jaccottey, L. and Farget, V. (2011): “Les normes de dessin des meules rotatives”, in: Buchsenschutz, O. et al. (coords), 2011, 51-68.

- Jaccottey, L, Alonso N., Deffressigne S., Hamon, C., Lepareux-Coluturier, S., Brisotto, V., Galland-Crety S., Jodry F., Lagadec J.-P., Lepaumier H., Longepierre S., Milleville A., Robin B. and Zaour N. (2013): “Le passage des meules va-et-vient aux meules rotatives en France”, in: Krausz, S., Colin, A., Gruel, K., Ralston & I. Dechezlepretre, T., (eds), L’âge du Fer en Europe. Mélanges offerts à Olivier Buchsenschutz, 2013, Bordeaux, Ausonius Mémoires 23, 405-419.

- Jodry F. (2011): “Le Lexique”, in: Buchsenschutz, O. et al. (coords), 2011, 19-33.

- Kourouniotes, K. (1917): “Κιναιδοι µυλωθροι”, Ephemeris Archeologihe, 1917, 151-157.

- Moritz, L.A. (1958): Grain-Mills and Flour in Classical Antiquity, Oxford.

- Peacock, D.P.S. (2013): The Stone of Life: The Archaeology of Querns, Mills and Flour Production in Europe Up to C. AD 500, Highfield Press, Volume 1, Southampton Monographs in Archaeology New Series, Southampton.

- Py, M. (1992): “Meules d’époque protohistorique et romaine provenant de Lattes”, Lattara, 1992, 5, 183-232.

- Robinson, D.M. and Graham, J.-W. (1938): Excavations at Olynthus, Vol. 8, Johns Hopkins University Press, Baltimore.

- Rostovtzeff, M. (1937): “Two homeric bowls in the Louvre”, AJA, 1937, 86-96.

- Wefers, S. (2009): “Neue Mühlen aus dem Osten: ‘Olynthische Mühlen’ auch in Thüringen und Bayern”, Beiträge zur Vorgeschichte Nordostbayerns, 2009, 7, Nürnberg, 149-158.