Introduction: A new mineral age evolves

Mining goes back much earlier and begins at least in the Upper Palaeolithic. The extraction of red ochre is a very early and worldwide phenomenon,1 but initially there is no direct route from this early evidence to high-quality technical and logistical examples, as we saw them many thousands of years later in the 3rd and 2nd mill. BC in West Asia and Europe.2 Further developments must have come together here before complexly organized mining operations could arise, as this has been the case for the highly developed Eastern Alpine salt and copper mining centres since the 2nd mill. BC.3

The emergence of certain technical elements of a Eurasian ore mining in the Eastern Serbian Ore Mountains can be discussed, because here pigment mining should have stimulated the mining of ores for metal production, as it became significant especially from the middle of the 5th mill. BC onwards.4 Technical innovations such as fire-setting can be grasped for the first time here, as in the somewhat more recent jasper mining of Kleinkems.5 It is at least interesting that this techno complex consisted of a whole bundle of individual practices that had to be understood and combined with each other if the extraction was to be successful.6

This at least indicates that there have been transfers of knowledge by specialists, possibly entire knowledge spaces in which the exchange of goods, people and information was possible over a longer period of time. Here the Danubian Neolithization is the basic background of such flow of knowledge and people.7 For early metallurgy, the similar geological conditions of the TEMB (Tethyan-Euarasian Metallogenic Belt) might have been the necessary background for the distribution of pyrotechnics and fire-setting as an appropriate winning technique (fig. 1).

With the late 6th millennium, also the technical and organizational principles of the early Neolithic flint mining were established.8 which in Central Europe was used to disseminate knowledge complexes that spread via certain deposit formations, such as the Maastricht Formation from southern England to Poland and the Ukraine.9 With the shaft construction widened to the “Duckelbau” (coyoting), real mines emerged during the end of the 5th millennium, which were not only visited in the course of a single extraction operation, but repeatedly by the same working gangs. Here, not only was knowledge passed on over the generations, but probably also the rights of individual groups to use certain raw material claims.

With the production of large and prestigious axes, another important aspect is impressively demonstrated, especially in the late 5th and early 4th millennia.10 With the “mineralization” of prehistoric communities, prestigious object classes in particular have found their way into the communities, e. g., objects that obviously played a differentiating role in social activities and possibly brought individual groups and persons into a dominant role in the entirety of the communities involved in agricultural activities. Phenomena such as Varna and Carnac are representative of the social effects of increasing “mineralising” of societies of the 5th and early 4th mill. BC.11 With a view to the materials themselves, certain substances seem to have been appropriated in different ways and embedded in specific social practice. Metal is by no means the only important substance. Rather, we see very different materials: long obsidian or silex blades, so-called super-blades, as well as excellently polished axes (such as jadeite and serpentinite), colourful stones or metal.12 It is not for nothing that this increased social need for badges and special materials goes hand in hand with numerous other dynamics that we have seen since the 5th mill. BC in different areas of the Old World. Additional developments have to be mentioned here, as the settlement densification in individual core zones as well as the development of the country in hitherto secondary usable areas (e.g. the circumalpine landscapes with settlements on the lakeshores).13

Transitions and the evolvement of new concepts

It is of great importance for our debate to understand the production practices as societal enmeshments and activities. The appropriation of materials and objects inherits all the practice that producers and consumers had with them (in a broader sense as affordances within human practices).14 This for instance gets clear when regarding tribal societies in the Western Pacific and their specific access to the procurement of raw materials such as prestigious stones, salt or obsidian. It is the societal action that is important and displays a part of the ideological concept that is attributed to the objects, relying on how and as part of which action the raw material had been achieved. Mining experts and leaders are not only those who know about the technical work flow but also about the ritual narratives and necessary action – a second “work flow” one could call it.15

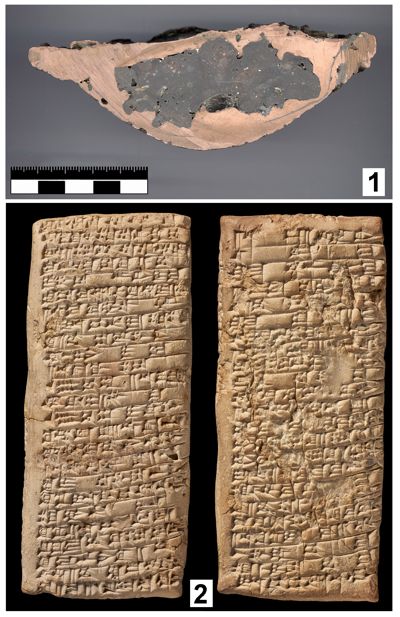

Direct access to raw materials is certainly the oldest basic mode of exploitation. During the 4th and 3rd mill. BC, the provision modes have changed and here we see first longer lasting mining districts and trading networks that connected regions and producers in a more stable relation. What researchers called partly the relation between highlands and lowlands, between the agricultural centers and the mineral resource rich highlands, became now a dominant and latent interrelation in exchange of ideas, peoples, goods and conflict. As it may seem, raw material procurement and husbandry to the mountainous hinterland were the most important driving forces. Once Andrew Sherratt called such the “Secondary products” revolution and listed animal products such as milk, cheese or wool on the first hand.16 However, criticized for its first very general conceptualizing.17 the idea of including secondary resource-scapes may grasped here again. More permanency in relations between different resource-scapes resulted in the transition of directly accessed resources to the trading of commodities. This not only required some kind of dichotomy between producers and consumers and therefore led to a more externalized relation to resources. Traded commodities like salt, wool, cheese or metals had to be weighed and described as well as they had to be proven according to their qualities. Therefore, it is clear that the appropriation of raw materials to resources underwent various steps. First did the usage and practice with things and substances raise experience, knowledge, but later also triggered a desire for them: this is the moment in which resources were not seen any longer purely as daily goods of practice but also as worthy equivalents, which had to be administered when barter-trade evolved.18 Administered trade opened the doors for more stable and larger access to raw materials but also for cheating. Well known is the evidence of cheating documented at cuneiform tablets from Sumerian southern Mesopotamia in the 3rd millennium BC19 (fig. 2,2). If we look at Bronze Age ingots from Oman peninsula, from Aqiir and Ra’s al Hadd that manifest a false core consisting of copper matte or even slag, we clearly understand these complaints (fig. 2,1).20 This cheating is certainly also an expression of certain alienation of the product from oneself and the own societal nuclear-group in the frame of a commoditization of goods.21

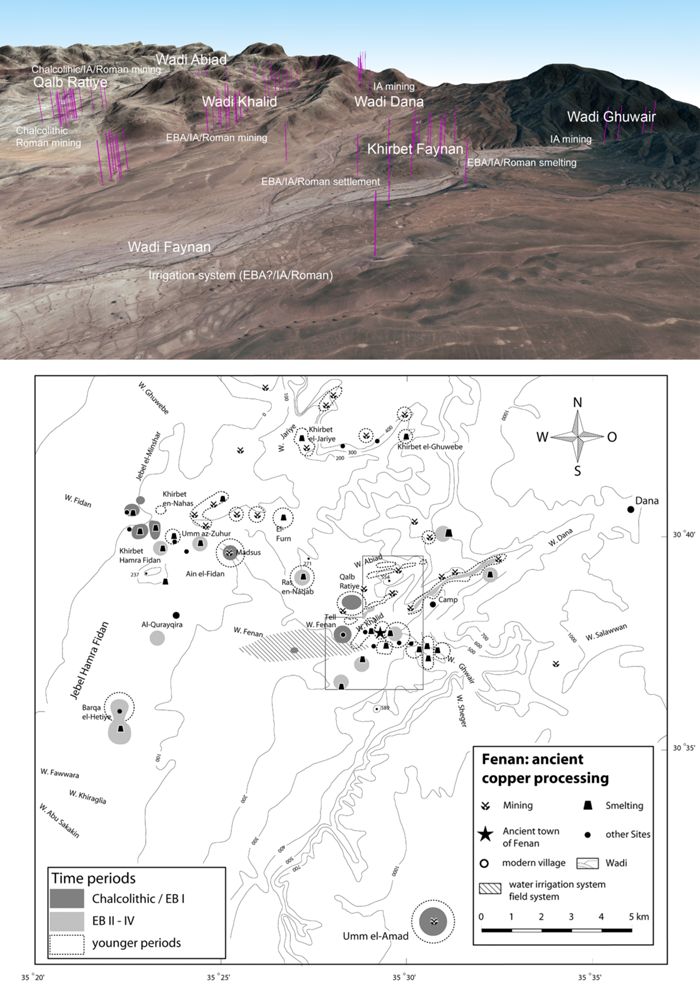

It is certainly worth thinking how such secondary resource-scapes could evolve to mining and metallurgical centers. In addition, how the seasonal, small scale production gradually changed to permanent winning in larger scale and how this again changed also the social complexity of a society. One of the best examples is certainly the mining area of Fenan in the Southern Levant where the transition of a non-permanent copper-ore exploitation of the 5th and early 4th mill. BC changed to a permanent winning strategy in the late 4th and 3rd millennium.22 Fenan lies on the border of the Jordanian Plateau and the Wadi Arabah and can be seen as a major supplier of copper to the southern Levant, especially since the second half of the 4th millennium and in the 3rd millennium. The development of the Fenan copper ore district during this period shows a continuous integration of the deposit area as a settlement and economic area. For the first sporadic use of copper as early as the 5th millennium, settlements were founded on the edge of the mining area in Wadi Fidan.23 These were geared towards supplying the miners and processing the copper. Over time, the settlements were pushed more along the Wadi into the ore deposit zone, before a central settlement is established in the central mining areas around Wadi Khaled in the Early Bronze Age at Wadi Fenan24 (fig. 3). At the same time, agricultural activities are documented for the first time and separated and large smelting sites were created outside the settlements. Since the supply of fuel and food was precarious, this not only led to a dependency on external supplies and bio-resources (such as forest stands), but also likely resulted in a fragile system of supply.25 With Fenan we see for the first time the consequences that could arise from the increased demand for metal raw materials, up to and including the abandonment of the mining area after the presumed exhaustion of fuel resources at the end of the 3rd millennium. Further examples are now known and spread from the Iranian plateau to Anatolia and the Caucasus (e.g. the Göltepe-Kestel, Arisman and the Sakdrisi-Dzedzvebi-complex).26

One of these other cases shows even more impressively how a sporadic strategy of raw material use could be turned into a more or less permanent extraction. The example of the gold mining of Sakdrisi in Georgia leads us back to the middle and the second half of the 4th millennium and is therefore as old as the examples of Arisman and Fenan. In the deposit area of Bolnisi Madneuli, copper and maybe even precious metals were extracted as early as the late 5th millennium. But it was not until the second half of the 4th millennium that mountain gold was extracted from the rich free gold deposit on the hill of Kachagiani, which also led to a more permanent settlement on the nearby plateau of Balichi-Dzedzwebi.27 In addition to a residential area on the southern plateau, a workshop area is also established there, in which the gold ore was further processed on a large scale. Both the finds from the mine (ceramics) and from the settlement show that different groups were involved in the gold extraction, they probably came to the valley for gold mining and had to get in touch with the regional groups there. As the high ritualization of the various work steps in the settlement shows, residents and “foreigners” formed a ritual community of gold mining28 (fig. 4). They were probably also closely linked to the further embedding of the metal in social processes. The example of Sakdrisi clearly shows how the earlier outlined older concept of the direct appropriation of raw materials and the associated social charge of the material obtained have changed. The workshop settlement shows the processing of gold and how the standardized practices of gold processing were intensified in the time around 3000. It is a time when gold and other special materials came back into the graves more and more and thus triggered a higher social need:29 ultimately, it is this increased need that also triggered the change in the sphere of raw material production. They went hand in hand with the commoditization of raw materials and a now commercialized trade. It is not by chance that this changed relationship is now initiating a development that ultimately continues with industrialized mining to this day. It is interesting that in the course of this process, entire landscapes and societies are ultimately included in this raw material commercialization. The resource-scapes are now more “total” and shaped not only large mining areas but communities and economies as a whole.

The growth of technical knowledge and economic stability: Large scale mining landscapes in the 2nd and 1st mill. BC

During the 3rd millennium, the old world has changed and this also tangled the areas of temperate Europe: mining and metallurgy extended to several areas as Spain, Southern France, the Eastern Alps and the Slovakian Ore Mountains.30

With the bell beakers, the strategies geared towards the use of entire landscapes and resource foci that became now intensified. It was the first time that the appropriation of entire landscapes was directly linked to the extraction of raw materials. Examples like the fahlore mining district of Cabrières demonstrate impressively the continuous incorporation of these secondary resource-scapes by founding also settlements inside the ore district.31 Expeditions and journeys to the sources were not any longer the only strategy followed. This is also evident for the British Isles with the introduction of a bell-beaker tradition metallurgy. In the west of Ireland (Ross Island) but also in Wales it appears that this bell-beaker horizon seems to be the basis of a later and then continuous early to mid-Bronze Age mining development that opened up the whole landscapes.32

This also established long-lasting path dependencies within these environments landscapes, which have led to continuous use, in some cases for several centuries. The nature of this knowledge bundles is particularly interesting for us, as those processes established not only a continuous growth of knowledge in handling the raw materials and their environments themselves. Further levels of knowledge were required now: handling of logistic concepts in supplying groups to maintain their continuous work, for instance.

The Alpine raw material landscapes are a good example here33 (fig. 5,1); their development, especially in the central areas, followed a first late Copper Age initial phase, which can only be evidenced indirectly in the Inn Valley to this day.34 Only with the development of the Salzach Valley and the large mining area around the Mitterberg it became possible to establish a permanent extraction concept that made it possible for settler communities to survive in the Alpine valleys.35 The basis was a technical, but also a social and economic concept that followed a clear operational concept that we now call the Mitterberg process36 (fig. 5,2). In order to clarify the dimensions of copper production in the Mitterberg mining district, it may be important to first take a look at the assumed amount of copper produced. In the mines of the main lode, around 700,000 tons of ore-bearing rock and debris were extracted from the pits, which stretched up to 140 m into the depths; this corresponded to 17,110 t copper content. The main lode district produced around 15,000 t of black copper, we can accept up to 24,000 t of black copper from the whole Mitterberg mining region, which was produced during the entire operating period between the 18th and the 9th centuries, but to a large extend between the 16th and the 12thcentury respectively.37 As we know today, Mitterberg copper has supplied large parts of eastern Central Europe, from southern Scandinavia to the northern Carpathian Basin, since the late Early Bronze Age. It was not until the late 14th century that other alpine producers added their products to the trading networks, and ultimately not only Mitterberg copper but also alpine copper as a whole became an essential basis for copper and bronze production in southern Central Europe.

The mining, beneficiation and smelting of sulphidic copper ores was the backbone. The process itself involved the extraction, the pre-processing (beneficiation and/or roasting), the smelting of such ores and finally the fabrication of black copper as a raw product. Given a specific level of technical experience, one can propose a several-step process that one may describe within a chaîne opératoire.38 This proposed model logically depends upon the complexity of techniques and procedural steps being involved to generally complex strategies of dwelling in these rarely colonized environments at the beginning. But more than that: chalcopyrite, if produced in masses, also allowed regular alloying with tin to a predictable product, the bronze. A larger producer like the Mitterberg not only required knowledge but also a deposit that allowed such a production. It certainly also required stable trading networks that guarantied availability of supply goods and raw materials such as tin.39

But how did this extraordinary development come about? This is probably not only due to the quality of the regional copper deposits. Two specific further aspects are to consider, i.e., i), the appropriation of the environment, which led to a total appropriation of the secondary resource spaces that are closely interwoven through knowledge building and specified practices; and ii) it is interesting how this complex of interweaving has expanded over time to the eastern part of the Alpine arc.40 We see some surprising similarities but also clear differences between the individual production areas. The transfer of technology is likely to have been carried out by specialists who then incorporated further settlers from the foothills of the Alps and thus established new production sites.

Following Tim Ingolds work on environmental perception,41 it is interesting to consider how Alpine dwellers did entangle with the Alpine environment they found when they came to regions like the Salzach Valley, the Inn-Valley, the Oberhalbstein or the eastern Trentino. They made specific experiences that formed their daily practice within those landscapes. Although the daily practices might be similar in all these areas, there certainly have been important differences in climatic situation, the Alpine borderline of forests, the relation to transport and wayfaring but also the access to arable land in the different valleys,42 This has certainly influenced the various communities. It influenced their choices for instance to engage with copper production or not.

The process of conversion to a copper-producing region began on a large scale from the 15th and 14th c. BC.43 In many regions, copper extraction has thus become an important economic strategy for the Alpine settler groups, who always lived in precarious agricultural supply conditions. This also created specific knowledge spaces, which were also reflected in specific cultural patterns in the course of development.

Once people have established their daily practices, a possibly slightly grown–up knowledge which became a matter of a longer lasting cultural memory within the groups. It probably was handed down over generations and also was expressed in specific cultural pattern, by a specific incorporation of specific technical and ritual practices, by specific display of wealth and social structure and finally by a pattern of cultural groups that we can distinguish by their material culture worlds.44

Conclusions

So let me summarize at the end. In the course of the very long period of 3000 years, the extraction of mineral raw materials, especially metals, has seen an enormous change, which ultimately led to the alienation of prehistoric societies to the materials and resources they used. In the 5th and also in the 4th mill. BC, the prehistoric societies between West Asia and continental Europe appropriated the desired raw materials themselves. The raw materials were embedded

in the groups themselves through the practice of winning and were incorporated ideologically in the value system of societies. Expeditions and trips to the raw materials have also contributed significantly to the social status of individual social groups. The disposition of status-giving materials had hardly been separated from the knowledge and origin tied to them. With the commodization and commercialization of goods, a process that we can initially observe in the landscapes between the southern Levant and the Indus Valley, the first alienation between producers and consumers sets in. It is not only the exchange that becomes commercialized, but the producers develop knowledge bases which allowed them to satisfy the increased demand for mineral raw materials, but also to achieve better subsistence conditions for themselves overall. Ultimately, this Bronze Age world now faces the concept of raw materials as goods and the control of such goods produced in large quantities by networks of demand and social interrelationships.

Bibliography

- Adams, R., Genz, H. (1995): “Excavations at Wadi Fidan 4: A Chalcolithic Village Complex in the Copper Ore District of Feinan, Southern Jordan”, Palestine Exploration Quart., 127, 8-20.

- Ambert, P. (1995): “Les mines préhistoriques de Cabrières (Hérault): Quinze ans de recherches. État de la question“, BSPF, 92, 499-508.

- Ambert P., Bouquet L., Guendon J.L., Mischka D. (2005): “La Capitelle du Broum (District minier de Cabrières-Péret, Hérault): établissement industriel de l’aurore de la métallurgie française (3100-2400 BC)”, in: Ambert P. and Vaquer J. ed. : La première métallurgie en France et dans les pays limitrophes, Mémoires de la SPF 37, Paris, 83-96.

- Barber, M., Topping, P., Field D. (1999): The Neolithic Flint Mines of England, Swindon.

- Barker, G.W., Gilbertson, D.D., Mattingly, D.J. ed. (2007): Archaeology and Desertification: The Wadi Faynan Landscape Survey, Jordan. Oxford.

- Beaumont, P. (1973): “The Ancient Pigment Mines in Southern Africa”, South African Journal of Science, 69, 140-146.

- Borić, D. (2009): “Absolute dating of metallurgical innovations in the Vinča Culture of the Balkans”, in: Kienlin, T. L. and Roberts, B. W., ed.: Metals and Societies. Studies in Honour of Barbara S. Ottaway. Universitätsforschungen zur Prähistorischen Archäologie 169, Bonn, 191-205.

- Burton, J. (1984): “Quarrying in a tribal society”, World Archaeology, 16/2, 234-247.

- Cassen, S. (2017): “D’un signe l’autre, des Alpes à l’Atlantique: représentant et représenté”, in: Pétrequin, P, Pétrequin, A.-M., Gauthier, E. ed. : Jade. Objets-signes et interprétations sociales des jades alpins dans l’Europe néolithique 3, Cahiers de la MSH Ledoux n°27, Besançon, 883-909.

- Consuegra, S., Castañeda, N., Capdevila, E., Capote, M., Criado, C., Casas, C., Nieto, A., Díaz-del-Río, P. (2018): “The Early Neolithic flint mine of Casa Montero (Madrid, Spain), 5350-5220 cal. BC.”, Trabajos de Prehistoria, 75-1, 52-66.

- Eibner, C. (1982): “Kupfererzbergbau in Österreichs Alpen“, in: Hänsel, B. ed.: Südosteuropa zwischen 1600 und 1000 v. Chr. Prähistorische Archäologie in Südosteuropa 1, Berlin, 399-408.

- Engel, T., Frey, W. (1996): “Fuel resources for copper smelting in antiquity in selected woodlands in the Edom highlands to the Wadi Arabah/Jordan”, Flora 191, 29-39.

- Gibson, J. J. (1977): “The Theory of Affordances”, in: Shaw, R. and Bransford, J. ed.: Perceiving, Acting, and Knowing: Toward an Ecological Psychology, Hillsdale 1977, 67-82.

- Craig, O. E., Chapman, J., Heron, C., Willis, L. H., Bartosiewicz, L., Taylor, G., Whittle, A., Collins, M. (2005): “Did the first farmers of central and eastern Europe produce dairy foods?”, Antiquity, 79, 882–894.

- Hansen, S. (2020): “Varna – Repräsentationen der Macht“, in: Hansen, S. ed.: Repräsentationen der Macht. Beiträge des Festkolloquiums zu Ehren des 65. Geburtstags von Blagoje Govedarica. Kolloquien zur Vor- und Frühgeschichte 25, Bonn, 45-72.

- Hauptmann, A. (2007): The Archaeometallurgy of Copper. Evidence from Faynan, Jordan. Natural Science in Archaeology, Berlin-Heidelberg.

- Hauptmann, A., Löffler I. (2013): “Technological Innovations and Organisational Structures of Prehistoric Mining and Metal Production – Examples from Faynan, Jordan”, in: Burmeister, S., Hansen, S., Kunst, M. and Müller-Scheeßel, N. ed.: Metal Matters. Innovative Technologies and Social Change in Prehistory and Antiquity,Rahden, 65-89.

- Helwing, B. (2011): “Conclusions: The Arisman Copper Production in a Wider Context”, in: Vatandoust, A. Parzinger, H. and Helwing B. ed.: Early Mining and Metallurgy on the Western Central Iranian Plateau. Report on the First Five Years of Research of the Joint Iranian-German Research Project, Archäologie in Iran und Turan 9, Mainz, 523-531.

- Hillebrandt, F. (2009): Praktiken des Tauschens. Zur Soziologie symbolischer Formen der Reziprozität, Wiesbaden.

- Ingold, T. (2000): The Perception of the Environment: Essays on Livelihood, Dwelling and Skill, London.

- Jovanović, B. (1982): Rudna Glava. Der älteste Kupferbergbau im Zentralbalkan, Posebna Izdania 17, Belgrad.

- Kern, A., Kowarik, K., Rausch, A., Reschreiter, H. ed. (2008): Salz-Reich. 7000 Jahre Hallstatt. Veröffentlichungen der Prähistorischen Abteilung des Naturhistorischen Museums Wien 2, Wien.

- Klassen, L., Pétrequin, P., Cassen, S. (2011): “The power of attraction … Zur Akkumulation sozial wertbesetzter alpiner Artefakte im Morbihan und im westlichen Ostseeraum im 5. und 4. Jahrtausend v.Chr.“, in Hansen, S., Müller, J. eds.: Sozialarchäologische Perspektiven: gesellschaftlicher Wandel 5000 – 1500 v. Chr. zwischen Atlantik und Kaukasus. Internationale Tagung, 15. – 18. Oktober 2007 in Kiel. Archäologie in Eurasien, 24, 13-40.

- Kopytoff, I. (1988): “The cultural biography of things: commoditization as process”, in: Appadurai, A. ed.: The social life of things. Commodities in cultural perspective, Cambridge, 64-91.

- Körlin G. and Weisgerber, G. ed. (2006): Stone Age – Mining Age, Der Anschnitt, Beiheft 19 (=VIII International Flint Symposium, Bochum 13 – 17 September 1999), Bochum.

- Krauß, R., Zäuner, S., Pernicka, E. (2014), “Statistical and anthropological analysis of the Varna necropolis“, in: Meller, H., Pernicka, E. and Risch, R. ed.: Metalle der Macht, Tagungen des Landesmuseums für Vorgeschichte Halle 11, Halle/Saale, 371-387.

- Levy, T.E., Adams, R. B., Hauptmann, A., Prange, M., Schmitt-Strecker, S., Najjar, M. (2002): “Early Copper Age metallurgy: newly discovered copper manufactory in southern Jordan”, Antiquity, 76, 425-437.

- Leroi-Gourhan, A. (1980): Hand und Wort – Die Evolution von Technik, Sprache und Kunst [1964/65], Frankfurt am Main.

- Löffler, I. (2020): Das prähistorische Montanrevier von Faynan in Jordanien. Studien zur Montanarchäologie der Kupfergewinnung in der südlichen Levante. PhD dissertation, Bochum.

- Oppenheimer, A. L. (1967): Letters from Mesopotamia. Official, Business, and Private Letters on Clay Tabletts on Two Millenia, Chicago, London.

- O’Brien, W. (2004): Ross Island. Mining, Metals and Society in Early Irland, Bronze Age Studies 6, Galway.

- O’Brien, W. (2015): Prehistoric Copper Mining in Europe. 5500-500 BC, Oxford.

- Pernicka, E., Lutz, J. and Stöllner, T. (2016): “Bronze Age copper produced at Mitterberg, Austria, and its distribution”, Archaeologia Austriaca, 100, 19-55.

- Pétrequin, P., Jeunesse, C. (1995) : La hache de pierre. Carrières vosgiennes et échanges de lames polies pendant le Néolithique (5400-2100 av. J.C.), Paris.

- Pétrequin, P., Pétrequin, A.-M. (2012) : “Les modèles ethnoarchéologiques de Nouvelle-Guinée“, in: Pétrequin, P., Cassen, S., Errera, M., Klassen, L., Sheridan, A. and Pétrequin, A.-M. ed.: Jade. Grandes haches alpines du Néolithique européen. Ve et IVe millénaires av. J.-C., Les Cahiers de la MSHE Ledoux 17, Série Dynamiques Territoriales 6, Besançon, 27-47.

- Prange, M. (2002): “5000 Jahre Kupfer im Oman“, in: Metalla (Bochum) 8,1/2, 1-126.

- Polanyi, K. (1944): The great transformation. New York/Toronto.

- Radivojević, M., Rehren, T., Pernicka, E., Šljivar, D., Brauns, M., Borić, D. (2010): “On the origins of extractive metallurgy: new evidence from Europe”, Journal of Archaeological Science, 37(11), 2775–2787.

- Roberts B., Thornton C, Piggott, V. (2009): “Development of metallurgy in Eurasia”, Antiquity, 83, 1012–1022.

- Rosenstock E., Scharl, S. and Schier W. (2016): “Ex oriente lux? – Ein Diskussionsbeitrag zur Stellung der frühen Kupfermetallurgie Südosteuropas”, in: Bartelheim, M. Horeijs, B., Krauss, R. ed.: Von Baden bis Troia. Ressourcennutzung, Metallurgie und Wissenstransfer. Eine Jubiläumsschrift für Ernst Pernicka. Oriental and European Archaeology Volume 3, Rahden, 59-122.

- Rind, M. M. ed. (2020): Das neolithische Hornsteinbergwerk von Abensberg-Arnhofen. Die Auswertung der Ausgrabungen 1998-2009, Materialhefte zur bayerischen Vorgeschichte 112, Kallmünz.

- Schier, W. (2009): “Extensiver Brandfeldbau und die Ausbreitung der neolithischen Wirtschaftsweise in Mitteleuropa und Südskandinavien am Ende des 5. Jahrtausends v. Chr.“, Praehistorische Zeitschrift, 84, 15–43.

- Schmid, E. (1999): “Der jungsteinzeitliche Abbau auf Silex bei Kleinkems, Baden-Württemberg (D1)“, in: Weisgerber, G., Slotta, R. and Weiner, J. ed.: 5000 Jahre Feuersteinbergbau. Die Suche nach dem Stahl der Steinzeit, Veröffentlichungen aus dem Deutschen Bergbau-Museum, 77, Bochum, 141-165.

- Shennan, S.J. (1995): Bronze Age Copper Producers of the Eastern Alps: Excavations at St. Veit-Klinglberg, Universitätsforschungen zur prähistorischen Archäologie 27, Bonn.

- Shennan, S. (1999): “Cost, benefit and value in the organization of early European copper production”, Antiquity, 73, 352-363.

- Sherratt, A. (1981): “Plough and Pastoralism. Aspects of the Secondary Products Revolution”, in: Hodder, I., Isaac, G. and Hammond, N. ed.: Pattern of the Past. Studies in honour of David Clarke, Cambridge, 261–305.

- Sherratt, A. (1983): “The secondary exploitation of animals in the Old World”, World Archaeology, 15, 90-104.

- Sperber, L. (1992): “Zur Demographie des spätbronzezeitlichen Gräberfeldes von Volders in Nordtirol“. Veröffentlichungen Tiroler Landesmuseum Ferdinandeum, 72, 37-74.

- Stöllner, T. (2005): “Mineralische Rohstoffe der Bronzezeit – ein Überblick aus dem Blickwinkel des ostmediterranen Raumes“, in: Yalçın, Ü., Pulak C., Slotta R. ed.: Das Schiff von Uluburun. Welthandel vor 3000 Jahren, Katalog zur Ausstellung des DBM, Bochum, 451-474.

- Stöllner, T. (2008): “Mining Landscapes in Early Societies – Imprinting Processes in Pre- and Protohistoric Economies?”, in: Bartels, C., Küpper-Eichas, C. ed.: Cultural Heritage and Landscapes in Europe. Landschaften: Kulturelles Erbe in Europa. Proceedings International Conference Bochum 2007, Veröffentlichungen aus dem Deutschen Bergbau-Museum Bochum 161, Bochum, 65-92.

- Stöllner T. (2009): “Prähistorische Montanreviere der Ost- und Südalpen – Anmerkungen zu einem Forschungsstand“, in: Oeggl, K. and Prast, M. ed.: Die Geschichte des Bergbaues in Tirol und seinen angrenzenden Gebieten. Proceedings zum 3. Milestone-Meeting SFB HiMAT 2008, Innsbruck, 37-60.

- Stöllner, T. (2010): “Copper and Salt – Mining Communities in the Alpine Metal Ages”, in: Anreiter P. et al. ed.: Mining in European History and its Impact on Environment and Human Societies. Proceedings 1st Mining in European History –Conference SFB HiMAT 12.-15. November 2009, Innsbruck, 297-314.

- Stöllner, T. (2015): “Der Mitterberg als Großproduzent für Kupfer in der Bronzezeit“, in: Stöllner, Th. and Oeggl, K. ed.: Bergauf Bergab. 10000 Jahre Bergbau in den Ostalpen. Wissenschaftlicher Beiband zur Ausstellung Bochum und Bregenz. Veröffentlichungen des Deutschen Bergbau-Museums Bochum 207, Bochum, 175-185.

- Stöllner, T. (2017): “Resources, innovation, technology. Theoretical approaches to abstract concepts and research content”, in: Eisenach, P., Stöllner, T. and Windler, A. ed.: The RITaK conferences 2013–2014. Raw Materials, Innovation, Technology of Ancient Cultures RITaK 1, Der Anschnitt, Bd. 34, Rahden/Bochum, 11-23.

- Stöllner, T. (2016): “The Beginnings of Social Inequality: Consumer and Producer Perspectives from Transcaucasia in the 4th and the 3rd Millennia BC”, in: Bartelheim, M. Horeijs, B. and Krauss, R. ed.: Von Baden bis Troia. Ressourcennutzung, Metallurgie und Wissenstransfer. Eine Jubiläumsschrift für Ernst Pernicka. Oriental and European Archaeology Volume 3, Rahden, 209-234.

- Stöllner, T. (2019): “Enmeshment within Resource-Scapes – Eastern Alpine Copper Production of the Bronze- and Early Iron Age“, in: Turck, R., Stöllner, T., Goldenberg, G. ed.: Alpine Copper II – Alpenkupfer II – Rame delle Alpi II – Cuivre des Alpes II. New Results and Perspectives on Prehistoric Copper Production, Der Anschnitt, Beiheft 42, Rahden/Bochum, 13-30.

- Stöllner, T., Gambashidze, I. (2017): “The ritual interplay: gold mining practices in the late 4th and early 3rd millennia BC. With an appendix from T. Skowronek, A. Courcier”, in: Eriksen, B.V., Abegg-Wigg, A., Bleile, R. and Ickerodt U. ed.: Interaktion ohne Grenze. Festschrift für Claus von Carnap-Bornheim zum 60. Geburtstag, Schleswig, 119-136.

- Stöllner, T., Gambashidze, I. (2018): “Das prähistorische Siedlungsplateau Dzedzwebi nahe Balitschi in Unterkartli“, in: Giemsch, L. and Hansen, S. ed.: Gold & Wein. Georgiens älteste Schätze. Begleitband zur Sonderausstellung Frankfurt 2018/2019, Mainz, 150-157.

- Stöllner, T., Ġambašiże, I., Hauptmann, A., Mindiašvili, G., Gogočuri, G., Steffens, G. (2010): “Goldbergbau in Südostgeorgien – Neue Forschungen zum frühbronzezeitlichen Bergbau in Georgien“, in: Hansen, S. Hauptmann, A., Motzenbäcker I., Pernicka E. ed.: Von Majkop nach Trialeti – Gewinnung und Verbreitung von Metallen und Obsidian in Kaukasien im 4.-2. Jahrtausend v. Chr. Beiträge des internationalen Symposiums in Berlin vom 1.–3. Juni 2006. Kolloquien zur Vor- und Frühgeschichte 13, Bonn, 103-138

- Stöllner, T., Craddock, B., Gambaschidze, I., Gogotchuri, G., Hauptmann, A., Hornschuch, A., Klein, F., Löffler, I., Mindiashwili, G., Murwanidze, B., Senczek, S., Schaich, M., Steffens, G., Tamasashvili, K., Timberlake, S. (2014): “Gold in the Caucasus: New research on gold extraction in the Kura-Araxes Culture of the 4th millennium BC and early 3rd millennium BC. With an appendix of M. Jansen, T. Stöllner, A. Courcier“, in: Meller, H., Pernicka, E. and Risch, R. ed.: Metalle der Macht, Tagungen des Landesmuseums für Vorgeschichte Halle 11, Halle/Saale, 71-110.

- Strahm C., Hauptmann, A. (2009): “The metallurgical developmental phases in the Old World”, in: Kienlin, T. L. and Roberts, B. W., ed.: Metals and Societies. Studies in Honour of Barbara S. Ottaway. Universitätsforschungen zur Prähistorischen Archäologie 169, Bonn, 116–128.

- Strathern, M. (1965): “Axe type and quarries. A note on the classification of stone axe blades from the Hagen area, New Guinea“, The Journal of Polynesian Society 74, 182-191.

- Timberlake, S. (2009): “Copper mining and metal production at the beginning of the British Bronze Age”, in: Clark, P. ed.: Bronze Age Connections, Oxford, 95–122.

- Thomas, P. (2018): Studien zu den bronzezeitlichen Bergbauhölzern im Mitterberger Gebiet. Mitterberg-Forschung 1 (= Der Anschnitt, Beiheft 39), Rahden/Bochum.

- Thornton, C. (2009): “The Emergence of Complex Metallurgy on the Iranian Plateau: Escaping the Levantine Paradigm”, Journal of World Prehistory, 22, 301-327.

- 4000 Jahre Pfahlbauten (2016): 4000 Jahre Pfahlbauten. Begleitband zur Großen Landesausstellung Baden-Württemberg 2016, Osterfildern.

- Kassianidou, V. (2013): “Mining Landscapes of Prehistoric Cyprus”. Metalla (Bochum) 20.1, 36-45.

- Vosteen, M. (1996): Unter die Räder gekommen. Untersuchungen zu Sherratts „Secondary products revolution, Archäologische Berichte 7, Bonn.

- Weisgerber, G., Willies, L. (2001): “The Use of Fire in Prehistoric and Ancient Mining: Firesetting”, Paléorient, 26/2, 131-149.

- Weisgerber, G., Slotta, R., Weiner, J., ed. (1999): 5000 Jahre Feuersteinbergbau. Die Suche nach dem Stahl der Steinzeit, Veröffentlichungen aus dem Deutschen Bergbau-Museum 77m Bochum.

- Weisgerber, G., Pernicka, E. (1995): “Ore mining in prehistoric Europe: An overview”, in: Morteani G. and Northover J.P. ed.: Prehistoric Gold in Europe. Mines, Metallurgy and Manufacture, Nata ASI Series E 280, London, 159-182.

- Weisgerber, G. Cierny, J., C. Koukouli-Chrysanthaki, C. (2008): “Zu paläolithischer Gewinnung roter Farbmineralien auf der Insel Thasos”, in: Yalçın, Ü. ed.: Anatolian Metal IV. Der Anschnitt, Beiheft 21, Bochum, 179-190.

- Windler, A. (2018): Der Austausch von Spondylus gaederopus in Europa zwischen 5500 und 5000 v. Chr. Eine ökonomische Analyse, Der Anschnitt Beiheft 40 (=Raw Materials, Innovation, Technology of Ancient Cultures. RITaK 6), Bochum/Rahden.

- Yener, K. A. (2021): Göltepe excavations: tin production at an early Bronze Age mining town in the central Taurus Mountains, Turkey, Prehistory monographs 64, Philadelphia.

- Zschocke K., Preuschen, E. (1932): Das urzeitliche Bergbaugebiet von Mühlbach-Bischofshofen, Materialien zur Urgeschichte Österreichs 6, Wien: Selbstverlag der Anthropologischen Gesellschaft.

Notes

- Beaumont 1973; Weisgerber et al. 2008.

- Overviews see: Weisgerber & Pernicka 1995; Stöllner 2005; O’Brien 2015.

- Kern et. al. 2008; Stöllner 2010.

- Jovanović 1982; Borić 2009; Radivojević et al. 2010.

- Weisgerber & Willies 2001.

- Schmid 1999.

- The exchange of spondylus gaederopus shell is a good example for exchange networks in this frame: recently Windler 2018.

- Consuegra et al. 2018; Rind 2020.

- E.g. Barber et al. 1999; Weisgerber et al. 1999; Körlin & Weisgerber 2006.

- E.g. Pétrequin et al. 2012; Pétrequin & Jeunesse 1995.

- Varna: recently Krauß et al. 2014; Hansen 2020; Carnac: Klassen et al. 2011.

- Klassen et al. 2011; Cassen 2017; Hansen 2020.

- Schier 2009; 4000 Jahre Pfahlbauten 2016.

- Gibson 1977.

- Strathern 1965; Burton 1984; Pétrequin & Pétrequin 1993.

- Sherratt 1981; 1983.

- Vosteen 1996; Craig et al. 2005.

- The economic principles generalized by Polanyi 1944, 59-70; see also Hillebrandt 2009.

- Oppenheimer 1967; see also Stöllner 2017, 10-11.

- Prange 2002, 11-12 Fig. 6.

- See for the concepts of singularisation and commoditization: Kopytoff 1988.

- Summarizing: Hauptmann 2007; Barker et al. 2007; Hauptmann & Löffler 2013; see also the comment by Stöllner 2008, 80-86; for the mining evidence now Löffler 2020.

- Adams & Genz 1995.

- Levy et al. 2002; Hauptmann 2007; Barker et al. 2007, 229-270.

- Engel & Frey 1996.

- Thornton 2009; Helwing 2011; Stöllner et al. 2010; 2014; Yener 2021.

- Stöllner & Gambashidze 2018.

- Stöllner & Gambashidze 2017.

- Stöllner 2016.

- Look at more recent discussions: Strahm & Hauptmann 2009; Roberts et al. 2009; Rosenstock et al. 2016; O’Brien 2015.

- Ambert 1995; Ambert et al. 2005.

- O’Brien 2004; Timberlake 2009.

- Overview recently by various articles in: Stöllner & Oeggl 2015.

- T. Stöllner & U. Töchterle, in: Stöllner & Oeggl 2015, 117-120, 129-130.

- Overview about the recent research: Stöllner 2015; Thomas 2018; for older research see: Zschocke & Preuschen 1932; Eibner 1982.

- Shennan 1999; Stöllner 2010; 2019.

- Pernicka et al. 2016.

- Claude Leroi-Gourhan (1964) developed the idea of the chaîne opératoire for any productive practice, which is particularly used by archaeologist for any technical and productive process according to a rather mechanical concept, but in principle, the concept includes much more. Operation chains produced some kind of reliability and security in doing (at least an expectation), certainly also to convince groups to decide for colonizing and engaging in a business that at long last was precarious.

- Shennan 1999; Stöllner 2010; for 2nd millennium various large scale producers can be listed that fund their ore-basis in chalcopyrite deposits: e.g. Cyprus: e.g. Vasliki Kassianidou 2013; or Oman: e.g. Prange 2002.

- Eibner 1982; Stöllner 2009; 2019; O’Brien 2015, 163-184.

- Out of a large bibliography: Ingold 2000.

- Discussed with more detail: Stöllner 2019, esp. 23-25.

- A chronological development can be roughly outlined today: Stöllner 2009.

- In this direction already Sperber 1992; Shennan 1995; 1999; Stöllner 2010; 2019.